Plein Air wool (see our certification) is a key ingredient in all our mattresses. Sometimes the best technology is the oldest. We love to find innovative solutions, but there is no getting around the perfection of wool fiber for enhancing mattress performance. For this we have Mother Nature to thank.

Why Wool is Perfect

A mattress’s quilting directly affects your sleep temperature. While most U.S. mattress producers use non-breathable synthetic fibers like polyester to upholster and quilt their mattresses, Design Sleep uses wool. Sleep studies have shown that wool creates better temperature regulation, thereby lowering your heart rate and allowing you to sleep soundly—a big health incentive. Wool wicks moisture and allows it to evaporate, keeping you and your mattress drier. You sleep more comfortably, and your mattress does not become a breeding ground for allergens like mold, mildew, and dust mites. Wool is also a natural fire-retardant, so our mattresses comply with fire regulations while remaining chemical-free.

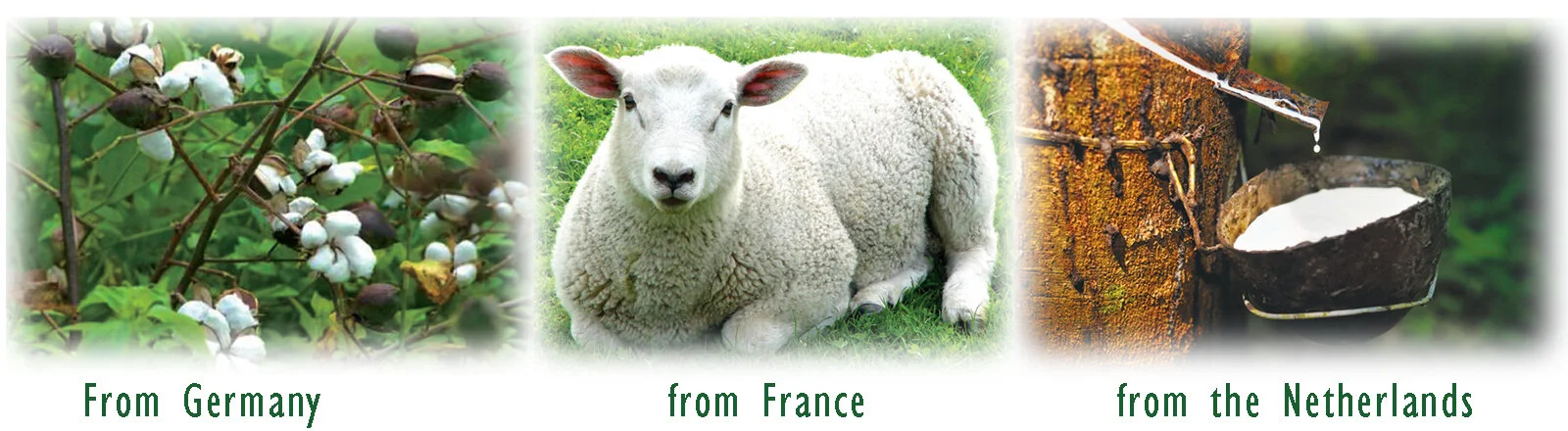

Our German-sourced wool is certified according to Oeko-Tex Standard 100, a strict set of European environmental guidelines. And our supplier uses a natural soda bath washing process to achieve the cleanest wool.

Wool provides the same advantages when it is used for bedding as it does inside your mattress. We offer twin, queen, and king-sized wool-filled duvets that are imported from Slovenia. They are warmer when you’re cold, cooler when you’re hot, and drier when it’s humid.

Plein Air Wool Features

Transports moisture: Better body temperature regulation and fewer allergens

Natural fire retardant: No chemicals needed

Durable: Wool’s natural crimp makes it exceptionally resilient

Certified to be chemically safe by Oeko-Tex. A clean, healthy fiber.

Excellent temperature regulator providing thermal balance

Moisture absorbing (up to 30% of weight/ synthetics max 4%)

Highly resistant to dust mites, mold and other allergens

Naturally flame retardant

Chemically safe

Plein-Air Wool®is the term used for wool that comes from sheep which live outside all year round. This livestock husbandry results in a naturally more curly and longer fiber, while providing the sheep a more humane habitat.

The strong natural curl provides lasting resilience, bounce and loft that is superior to mechanically crimped wool fiber which will matt down faster. The artificial crimping process used by some wool producers creates strain on the fibers causing them to break easier which results in shorter fibers. This has a direct negative effect on the long-term resilience and loft of the product.

There are zero chemicals used during the wool growing and processing steps. The sheep are not dipped or treated with any pesticides or herbicides.

After shearing, the wool goes through three washing cycles with increasing temperatures (90° - 140°F) followed by a cold rinse in pure water. During the washing cycles pure baking soda and water is used – nothing else. The drying takes place in drum driers and the wool is then cooled down on cooling racks for 24-28 hours before pressing and packaging.

After the washing process the lanolin (oil) content of the wool is less than 1%. This virtually eliminates the typical sheep odor and the risk of moth infestation. The plein-air wool is harvested from the back and belly only. This is a very important factor as usually wool for "fill" (as opposed to garments) also comes from the legs and crotch of the animal where it is impossible to completely wash out the smell.